Mon - Fri: 8am - 5pm, Sat - Sun: Closed

6-36 Month Warranties

We Ship Local.

Hablamos Español.

Connect with

Allison 1000/2000 Transmissions Buyer’s Guide

Transmissions Buyer's Guide

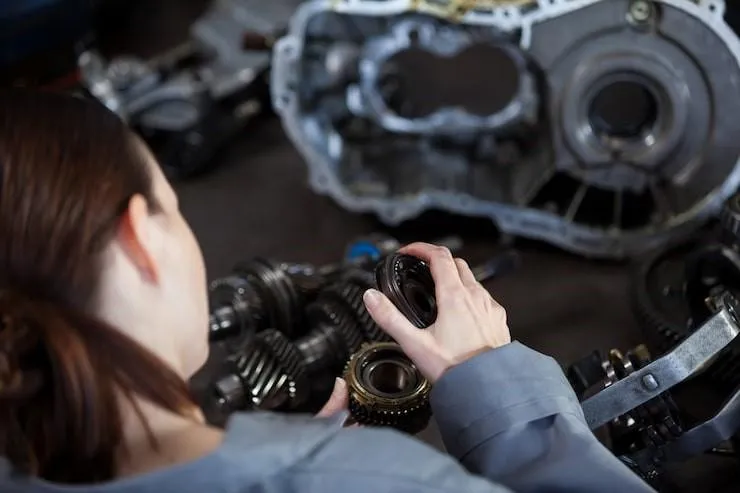

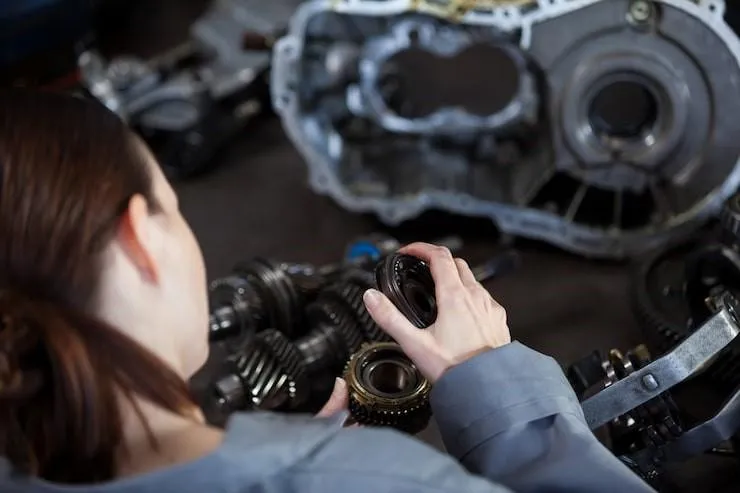

What Makes Allison Transmissions Unique

The Allison 1000 and 2000 series transmissions are known for durability, intelligent shift control, and refined performance. Built to handle diesel torque and heavy workloads, they set the standard for reliability in GM HD truck transmission applications. Unlike lighter-duty automatics, these models have stronger internals, robust clutch assemblies, and advanced thermal management for smoother towing and longer service intervals. Understanding how they function helps owners choose suitable service, rebuild, or replacement options.

Proper identification prevents costly mistakes. Always confirm the transmission’s serial tag, bellhousing style, and output spline count before ordering. Mismatched parts—like cross-generation valve bodies or incompatible torque converters—cause drivability issues or TCM calibration errors. Verify VIN, RPO code, and build sheet data for compatibility.

These transmissions are engineered for precision, performance, and longevity, making them ideal for both commercial and heavy-duty use. Regular maintenance, correct fluid levels, and proper calibration enhance their efficiency and extend operational life. Whether upgrading, rebuilding, or replacing, using genuine parts ensures compatibility and maintains factory reliability. The Allison 1000 and 2000 series continue to deliver consistent performance, supporting the strength and durability expected from every GM HD truck transmission.

Allison 1000 vs 2000 Series Differences

Both Allison 1000 and 2000 series transmissions share similar hydraulic architecture but differ in torque handling and cooling efficiency. The Allison 1000 is designed for light-duty 2500/3500 applications, providing smoother shifts for daily driving and mid-range towing. The Allison 2000 features heavier planetary gearsets, increased clutch surface area, a deeper oil sump, and a higher-capacity cooler, making it better for heavier workloads and continuous towing. Matching the transmission to the duty cycle ensures optimal lifespan, fuel efficiency, and reliable performance in GM HD truck transmission applications.

Recognizing wear signs like torque converter shudder, delayed gear engagement, or fluid discoloration is crucial for durability and intelligent shift control. Ignoring them can cause clutch damage or solenoid failure. Proper servicing with Allison fluid TES-295 and verifying serial tag, bellhousing style, and output spline count prevents compatibility issues and extends service intervals.

Proper maintenance requires confirming the VIN, RPO code, and build sheet data to ensure compatibility with replacement or rebuild components. Mismatched parts, such as cross-generation valve bodies or incompatible torque converters, can lead to TCM calibration errors and poor performance. Understanding these key factors helps owners avoid costly mistakes and ensures the reliable performance of Allison 1000 and 2000 series transmissions. This knowledge enables informed decisions about service, rebuild, or replacement options, maximizing transmission lifespan and efficiency.

Maintenance, Fluids, and Calibration Essentials

Maintaining consistent fluid pressure is essential for the reliable operation of Allison transmissions. It’s important to replace filters and fluid regularly, typically every 25,000 to 50,000 miles, depending on the vehicle’s duty cycle. Using Allison-approved TES-295 fluid is crucial because it maintains proper friction characteristics, preventing internal clutch slippage that can lead to premature wear or failure. Regular fluid changes not only ensure smooth shifting but also protect the transmission’s internal components from excessive heat and contamination.

Transmission overheating is the leading cause of failure in Allison 1000 and 2000 series transmissions. To prevent this, it’s vital to monitor cooler line temperature using a scan tool to verify cooling system efficiency. In towing or commercial applications where the transmission is under constant heavy load, installing an auxiliary cooler can be a worthwhile investment. This additional cooling helps reduce thermal stress on internal seals and bearings, extending transmission life and maintaining consistent performance under demanding conditions.

Calibration also plays a critical role in transmission health. After any major service, such as fluid changes or component replacements, performing a Transmission Control Module (TCM) relearn procedure is necessary. This process restores proper clutch fill times, preventing harsh or erratic shifting. It also maximizes clutch life and ensures that the transmission’s pressure and shift logic align with factory Allison specifications, helping the transmission operate smoothly and efficiently.

Finally, don’t overlook the electrical system. Inspect the wiring harness and ground points regularly, as electrical faults often mimic hydraulic problems. Voltage drops, poor grounds, or damaged connectors can cause intermittent failures that impact transmission operation. Addressing these electrical issues is essential to maintain consistent performance across both Allison 1000 and 2000 series transmissions, ensuring reliability and preventing unexpected downtime.

When a Rebuild or Replacement Is Needed

A full rebuild or replacement becomes necessary when consistent slip codes appear, fluid smells burnt, or metal debris shows in the pan. These signs indicate clutch or torque converter damage that partial repairs cannot fix effectively. Ignoring these symptoms can lead to severe transmission failure, resulting in costly repairs or total replacement. Timely and thorough action is crucial to restore the transmission’s reliability and performance, especially in demanding GM HD truck applications. Addressing the root cause prevents further damage and extends the life of your transmission.

Remanufactured Allison transmissions from Houston Engines undergo a full teardown, machining, and dyno testing process to validate pressure curves and shift quality, ensuring like-new performance. Each remanufactured unit includes new seals, clutches, solenoids, and verified Transmission Control Module (TCM) compatibility, all backed by warranty coverage for long-term peace of mind. Whether you are considering used transmissions or a complete rebuild, choosing the right solution is critical to maintaining peak performance and durability of your Allison 1000 or 2000 series transmission in your GM HD truck.

Installation Tips and Warranty Guidelines

Pre-installation steps play a vital role in determining the longevity of your Allison transmission. It is essential to flush the cooler lines thoroughly, replace heat exchangers, and verify converter spacing before mounting the transmission. Any residual debris from the old unit can quickly contaminate a rebuilt system, leading to premature wear and potential failure. Taking these precautions ensures a clean, efficient system ready for optimal performance.

Fluid fill procedures are temperature-dependent, so it’s important to use the correct level check range for Allison-approved TES-295 fluid. Proper fluid levels prevent overfilling or starvation, both of which can harm the transmission. After installation, completing a full TCM fast learn is critical for adaptive calibration. Skipping this step can cause erratic shifting, reduce clutch life, and negatively impact overall transmission performance.

Warranty coverage depends heavily on proper documentation. Be sure to keep receipts for all fluids, filters, and cooler replacements used during the installation process. Additionally, recording initial test readings—such as oil pressure, converter slip, and temperature—helps maintain warranty validity and proves installation accuracy. This documentation protects your investment and supports any future claims.

Houston Engines provides technical support, torque specifications, and core return guidance to simplify the installation process. Proper installation not only ensures long-term reliability and warranty compliance but also protects your GM HD truck transmission investment. For more details or to request service, don’t hesitate to contact Houston Engines — your trusted source for Allison rebuild expertise and transmission solutions.

Get our latest news and promos

QUALITY ASSURED

SATISFACTION GUARANTEED

UNPARALLELED SUPPORT

Houston Engines

Proud Member

Social Media

Payments Accepted

Ship Via