Mon - Fri: 8am - 5pm, Sat - Sun: Closed

6-36 Month Warranties

We Ship Local.

Hablamos Español.

Connect with

Expert Guide to American-Made Reman Diesel Engines

American-Made Reman Diesel Engines

Remanufactured diesel engines, especially those produced in the United States, are widely recognized for their high standards of quality, cost efficiency, and sustainability. These engines undergo rigorous rebuilding processes to ensure they perform as well as new ones, all while offering substantial cost savings and environmental benefits. In this guide, we will break down the advantages and essential considerations when selecting American-made remanufactured diesel engines.

What Are Remanufactured Diesel Engines?

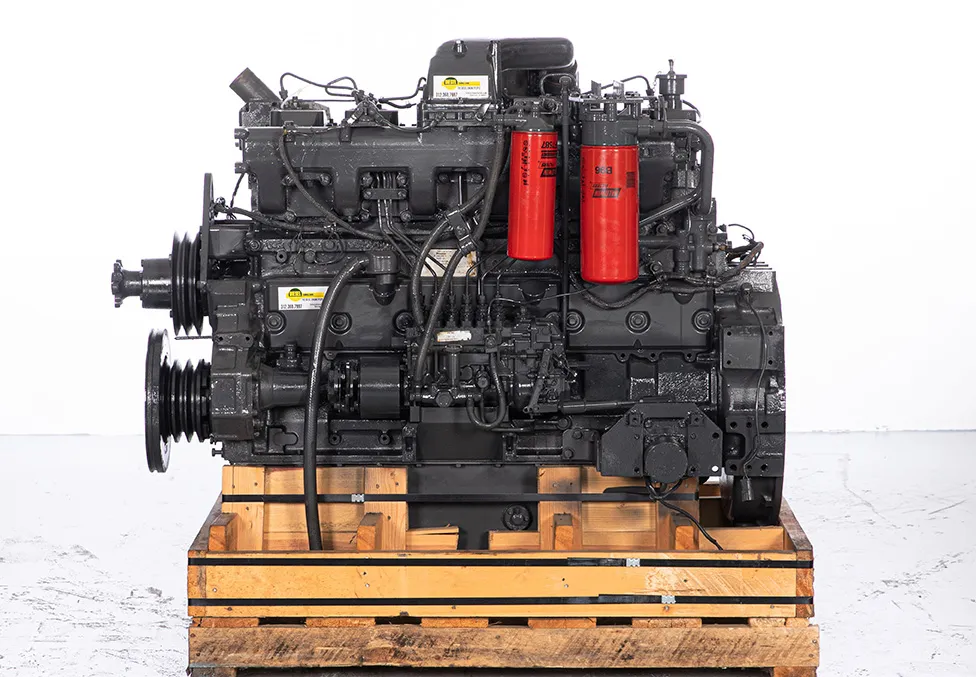

Remanufactured diesel engines go beyond simple repairs or rebuilds—they are completely restored to meet the original factory specifications. The process begins with a thorough teardown, during which every component is carefully inspected and cleaned. Any parts that fail to meet stringent quality standards are either re-machined or replaced with brand-new components.

This restoration process includes updating key parts like pistons, rings, bearings, and seals. In many cases, remanufacturers incorporate modern technological improvements to enhance engine efficiency and reduce emissions. The result is a fully reconditioned engine that delivers like-new performance. These engines are widely used in heavy-duty trucks, buses, industrial equipment, and agricultural machinery due to their reliability and cost-effectiveness. By extending the lifespan of a diesel engine, remanufacturing supports both economic and environmental sustainability.

Quality and Reliability

Remanufactured diesel engines must meet or exceed the strict quality benchmarks set by original equipment manufacturers (OEMs), ensuring consistent performance and reliability. Industry leaders such as JASPER are known for their meticulous quality control, subjecting each component to thorough testing and inspection before approval for use.

A remanufactured engine from JASPER undergoes a multi-step process where vital components, including fuel injectors, pistons, and bearings, are either replaced with new parts or reconditioned to achieve optimal functionality. This high level of precision extends the engine’s lifespan and improves fuel efficiency, making it a dependable option for personal vehicles, fleet operations, and industrial applications.

Many remanufactured engines come with strong warranties, further demonstrating the confidence manufacturers have in their products.

Cost-Effectiveness

Opting for a remanufactured diesel engine provides significant financial advantages over purchasing a brand-new one. In many cases, businesses and individuals can save up to 50% by choosing a remanufactured engine, making it an attractive choice for those looking to reduce costs without sacrificing quality or performance.

Beyond the initial savings, remanufactured engines typically have lower maintenance expenses over time. Many come with warranties comparable to those of new engines, offering added financial security. This cost-efficient approach allows vehicle owners and businesses to maximize their investment while ensuring the continued reliability of their equipment.

Environmental Benefits

Choosing a remanufactured diesel engine plays a crucial role in promoting environmental sustainability. The engine remanufacturing process significantly reduces waste by refurbishing and reusing major engine components, cutting down on the demand for new raw materials. This also helps minimize the number of discarded engines ending up in landfills.

Additionally, remanufacturing consumes less energy than producing a new engine from scratch, lowering the overall carbon footprint associated with manufacturing. Many remanufactured engines are also updated to comply with current emissions regulations, contributing to cleaner air and improved environmental responsibility. By selecting remanufactured engines, consumers and businesses actively support a more sustainable, resource-efficient economy.

Tips for Buying American-Made Reman Diesel Engines

When purchasing an American-made remanufactured diesel engine, several factors should be carefully evaluated to ensure the best decision.

✔ Warranty Coverage: is essential, as a comprehensive warranty indicates quality assurance and provides peace of mind. A good remanufactured engine should have a warranty comparable to that of a new one.

✔ Supplier Reputation: is another critical aspect. Buyers should research potential suppliers by reviewing customer feedback and industry ratings to determine their reliability and commitment to quality.

✔ Engine Compatibility: should also be verified to ensure that the remanufactured engine matches the technical specifications of the vehicle or machinery it will be installed in. Factors such as engine size, power output, and mounting points should be carefully checked.

✔ Certifications: play a key role in confirming the quality and compliance of remanufactured diesel engines. Engines that meet modern environmental and safety standards demonstrate adherence to high manufacturing standards.

✔ After-Sales Support: is crucial. Suppliers who provide readily available replacement parts and technical assistance can help ensure the long-term performance and reliability of the engine.

Let’s Wrap Things Up

American-made remanufactured diesel engines offer a combination of quality, affordability, and environmental responsibility. These engines meet strict performance requirements while helping reduce waste and energy consumption. For anyone considering an engine replacement, remanufactured engines present a reliable and cost-effective solution. Houston Engines provides a wide selection of remanufactured diesel engines designed to meet diverse needs while supporting a greener future.

Get our latest news and promos

QUALITY ASSURED

SATISFACTION GUARANTEED

UNPARALLELED SUPPORT

Houston Engines

Proud Member

Social Media

Payments Accepted

Ship Via