Mon - Fri: 8am - 5pm, Sat - Sun: Closed

6-36 Month Warranties

We Ship Local.

Hablamos Español.

Connect with

Ford 5.4L Triton Cam Phaser Issues

Ford 5.4 Cam Phaser Problems

Why the 5.4L 3V Develops Rattle

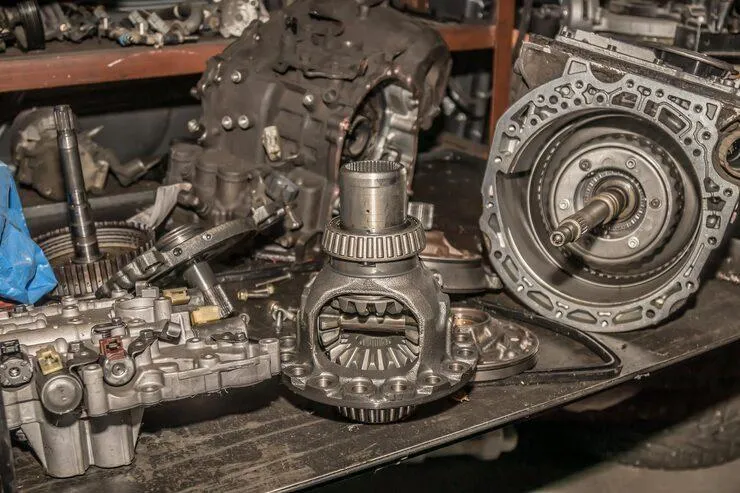

Ford’s 5.4L 3-valve Triton engines introduced variable cam timing for smoother operation, but the oil-actuated cam phasers quickly became a weak point. Low oil pressure, clogged passages, or worn tensioners can cause timing chains and phasers to chatter or drift out of alignment, leading to ticking or rattling noises that signal early wear.

This “diesel-like” rattle typically begins at idle and grows louder over time. Ignoring these early warning signs can result in piston-to-valve contact, severe internal damage, and costly repairs. Early diagnosis and intervention are critical to prevent complete timing failure. Houston Engines emphasizes addressing cam phaser and chain issues promptly to protect performance, preserve engine longevity, and avoid expensive top-end repairs.

Cam phaser problems often occur alongside stretched timing chains, collapsed tensioners, or worn guides. Left unresolved, these issues can cause rough idle, hard starting, or sudden power loss. Maintaining regular oil changes using high-quality 5W-20 synthetic oil and OEM-level filters helps ensure proper oil pressure, keeping cam phasers and timing components lubricated and functioning correctly. Proactive maintenance reduces wear, prevents premature failure, and extends the life of critical valvetrain and timing system components, protecting overall engine performance and reliability.

Repair and Replacement Decision Guidelines

Repairing a 5.4L cam phaser typically requires replacing phasers, timing chains, and tensioners, which can become expensive if cylinder head removal is necessary. For high-mileage engines showing signs of metal shavings, bearing wear, or other internal damage, a full engine replacement is often the more cost-effective and reliable option. Attempting partial repairs on worn components can lead to repeated failures and higher long-term expenses.

Houston Engines’ remanufactured 5.4L long blocks offer a turnkey solution with upgraded tensioners, improved oil pumps, and validated cam phasers featuring revised spool designs. Each engine is built to restore factory timing performance, eliminate rattle, and ensure smooth operation. Backed by comprehensive warranties, these reman engines provide long-term reliability, peace of mind, and restored performance for trucks, SUVs, and other vehicles equipped with Ford 5.4L 3-valve Triton engines.

For vehicles exceeding 150,000 miles, many shops recommend a remanufactured engine. Simple repairs often fail to address underlying oil pressure problems or internal bearing wear, leaving cam phasers and timing chains at risk of repeated failure. Installing a reman engine ensures all critical components, including phasers, chains, and tensioners, are rebuilt or upgraded to factory or improved specifications. This approach restores reliable performance, prevents costly repeat repairs, and extends engine life, providing peace of mind for high-mileage Ford 5.4L 3-valve Triton engines.

Cam Phaser Future Prevention Strategies

Maintaining consistent oil pressure is essential for preventing Ford 5.4 cam phaser problems. Using only high-quality oil filters ensures proper flow to the phasers, as lower-quality or budget filters may bypass oil too early, starving critical components of lubrication. Adequate oil pressure allows hydraulic timing control to function correctly, protecting phasers from premature wear and reducing the risk of chain or tensioner issues. Following OEM oil change intervals and using recommended synthetic oil helps maintain stable lubrication and prolongs the life of timing components.

Keeping PCV systems and oil return passages clean is equally important. Sludge buildup, aeration, or blockages can interfere with hydraulic timing control, causing uneven phaser operation and accelerated wear. Regular inspection and maintenance of PCV valves, along with ensuring oil passages are free of contaminants, help maintain proper phaser function. Clean passages allow oil to flow smoothly, reducing the likelihood of rattle, chatter, or timing drift in the Ford 5.4L 3-valve Triton engines.

During rebuilds or phaser replacements, verify timing cover alignment and install upgraded tensioners with stronger spring force. Proper assembly prevents early chain slack, minimizes phaser rattle, and ensures accurate cam timing. Neglecting these details can lead to repeated failures, noisy operation, and costly repairs. Using upgraded tensioners and aligning components correctly protects the valvetrain and improves long-term reliability, especially for high-mileage or high-load engines.

For fleet trucks, towing vehicles, or engines regularly under heavy load, consider switching to 5W-30 synthetic oil to maintain stable hot-pressure conditions. Consistent preventive maintenance—including high-quality oil, clean PCV systems, proper tensioner installation, and correct assembly practices—extends engine life well beyond factory expectations. These steps reduce the risk of costly Ford 5.4 cam phaser problems while ensuring reliable performance and long-term durability for demanding applications.

Deciding on a Remanufactured Engine

If timing chain noise continues after cam phaser replacement or oil pressure remains below specification, a remanufactured engine is often the safest and most reliable solution. Internal wear, metal debris, or worn bearings cannot be fully resolved by replacing external components alone, and attempting partial repairs may lead to repeated phaser failures or additional timing chain issues. Investing in a reman engine addresses all hidden wear, restoring proper oil flow and eliminating common causes of Ford 5.4 cam phaser problems.

Houston Engines’ reman units are meticulously cleaned, machined, and pressure-tested to maintain 70+ PSI hot oil pressure, ensuring consistent lubrication to the phasers, chains, and tensioners. Each engine is built to restore smooth operation, eliminate rattles, and provide long-term reliability. Backed by comprehensive warranties, these remanufactured engines offer peace of mind, protect against future timing failures, and deliver dependable performance for high-mileage or heavily used Ford 5.4L 3-valve Triton engines, making them a smart investment for owners seeking lasting durability and reduced maintenance concerns.

Engine Installation and Break-In Guidelines

Before starting a newly installed engine, it is essential to manually prime the oil pump. This ensures immediate oil pressure throughout the system, providing critical lubrication to hydraulic lifters, cam phasers, and timing components. Skipping this step can lead to dry starts, accelerated wear, or even early component failure. Proper priming guarantees that all internal passages are filled with oil before cranking, safeguarding the engine and promoting long-term durability.

During the first 500 miles, it is recommended to use break-in oil. Break-in oil helps seating of piston rings, lifters, and cam components, ensuring optimal performance and reduced wear. Avoid prolonged idle periods during this phase, as low oil flow can starve hydraulic lifters and timing components, potentially causing noise or premature failure. After the break-in period, switch to full synthetic oil to maintain consistent lubrication, improve thermal stability, and extend the engine’s overall lifespan.

Keeping detailed records of oil pressure readings, temperatures, and installation procedures is vital. Proper documentation validates warranty coverage and demonstrates that the engine was installed and maintained according to manufacturer recommendations. This protects your investment and ensures that any future warranty claims are supported with accurate data.

Houston Engines provides comprehensive installation guidance, nationwide shipping options, and warranty registration support. Whether you are a professional shop or a DIY installer, our technical team is available to provide advice, answer questions, and source remanufactured or used engines designed for high-mileage or performance applications. Following these steps ensures reliable operation, smooth break-in, and long-term engine durability.

Get our latest news and promos

QUALITY ASSURED

SATISFACTION GUARANTEED

UNPARALLELED SUPPORT

Houston Engines

Proud Member

Social Media

Payments Accepted

Ship Via