Mon - Fri: 8am - 5pm, Sat - Sun: Closed

6-36 Month Warranties

We Ship Local.

Hablamos Español.

Connect with

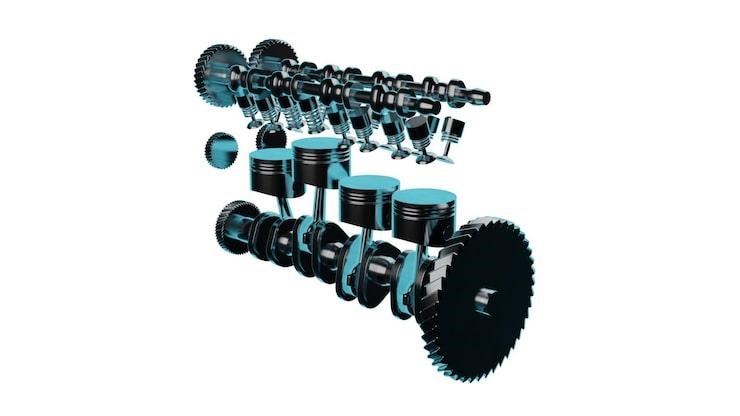

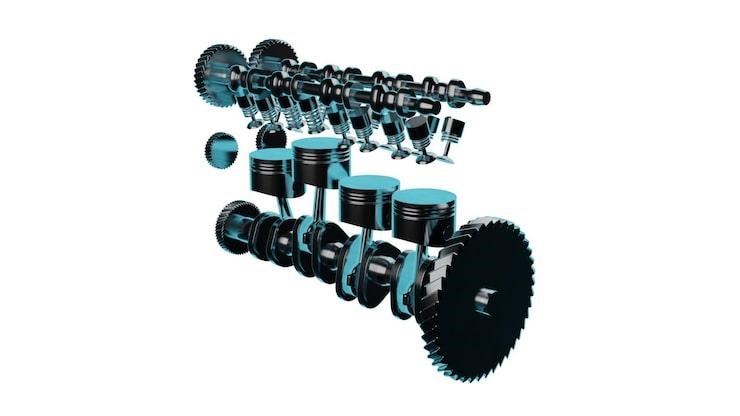

Ram ZF 8HP Transmission Overview

Ram ZF 8HP transmission

Duramax 6.6L Design and Reliability

The Ram ZF 8HP transmission is a major advancement in refinement and performance for the Ram 1500 and heavy-duty trucks. With eight forward gears, it delivers smooth torque transfer, improved fuel economy, and precise control under load. Its adaptive shift software adjusts to driver input and road conditions, optimizing clutch engagement and reducing wear. The ZF 8-speed is high-performing yet complex, requiring strict maintenance for reliability.

Long-term durability relies on consistent service. Neglecting fluid changes can lead to solenoid contamination, valve body scoring, or internal clutch slippage, causing delayed shifts, rough engagement, and torque converter issues, especially under towing or high-heat conditions. Proper fluid service and calibration updates ensure smooth, efficient operation.

ZF recommends fluid and filter changes every 60,000 miles, though frequent towing or heavy hauling may require shorter intervals. Using ZF Lifeguard 8 or Mopar ATF equivalents helps maintain internal seal integrity, stabilize hydraulic pressure, and ensure proper clutch engagement. Following this ZF 8-speed service schedule reduces long-term wear, prevents common Ram 1500 transmission problems from thermal stress and fluid breakdown, and supports reliable operation. Consistent maintenance ensures smooth shifts, efficient performance, and extended transmission life for all driving conditions.

ZF 8-Speed Service and Replacement Guide

Low-speed shudder, harsh gear changes, or inconsistent torque converter lock-up often result from contaminated or aged transmission fluid. Resetting the adaptive learning values after service allows the system to recalibrate shift pressure maps and restore smooth, optimal gear transitions. Performing this procedure with professional diagnostic tools is essential for maintaining drivability and preventing premature component failure, ensuring the ZF 8HP transmission continues to operate efficiently under all conditions.

In cases of severe internal damage, replacing the unit with a remanufactured transmission is the most cost-effective solution. Houston Engines offers ZF 8HP reman transmission options that are dyno-tested, recalibrated to factory specifications, and validated under load. Each reman unit provides balanced clutch engagement, precise hydraulic control, and reliable solenoid function, ensuring consistent long-term reliability for Ram trucks and other applications.

Each reman 8HP transmission includes a verified torque converter and a resealed valve body assembly to restore full operational integrity. These units undergo extensive testing to ensure proper pressure balance, thermal efficiency, and reliable performance. Designed to handle demanding conditions such as towing and high-speed driving, each reman 8HP provides smooth shifts, consistent clutch engagement, and long-term durability. Houston Engines’ reman units deliver dependable operation, maintaining ZF 8HP performance standards for Ram trucks and other applications.

ZF 8HP Transmission Wear Prevention Tips

Preventing premature wear in the Ram ZF 8HP transmission begins with managing operating temperatures. Avoid towing in extreme heat without an auxiliary cooler, as excessive temperature accelerates clutch degradation, fluid oxidation, and internal component wear. Transmission temperature should remain within the recommended range to preserve friction material life, reduce torque converter shudder, and maintain smooth gear engagement. Consistently monitoring temperature during demanding driving conditions helps prevent costly failures and ensures reliable performance under heavy loads, long trips, or frequent stop-and-go driving.

Software maintenance is equally important for long-term ZF 8HP reliability. ZF periodically issues calibration updates to improve shift logic, torque management, and adaptive clutch control. Outdated software can cause abrupt downshifts, delayed engagement, unnecessary torque converter cycling, and irregular shift quality. Performing calibration updates during routine service intervals enhances transmission smoothness, prevents drivability complaints, and ensures the transmission operates according to factory specifications under all conditions, including towing, hauling, and high-speed highway driving.

Fluid management is another critical factor in preventing premature wear. Always verify fluid temperature when filling or refilling, as ZF specifies a precise range between 86°F and 122°F for accurate level checks. Overfilling or underfilling can lead to aeration, hydraulic pressure loss, erratic shifts, and accelerated internal wear. Following proper fill procedures with factory-approved tools ensures correct fluid balance, optimal hydraulic performance, and consistent, reliable transmission operation over the lifespan of the vehicle.

Finally, maintain thorough service documentation to protect long-term dependability. Record mileage, fluid type, and calibration versions during each maintenance event. Using genuine ZF or Mopar seals and gaskets prevents leaks, avoids warranty complications, and supports resale value. A complete maintenance history demonstrates compliance, protects transmission longevity, and reinforces confidence in the performance and reliability of the Ram ZF 8HP transmission in all driving conditions.

When to Replace vs. Rebuild

When metallic debris is found on the pan magnet or clutch material appears in the fluid, a full transmission replacement is often the safest and most reliable solution. Attempting partial repairs on damaged valve bodies, torque converters, or clutch packs can lead to recurring issues, including shudder, slipping under load, erratic shifts, and premature wear. Replacing the entire assembly with a ZF 8HP reman transmission from Houston Engines ensures complete system restoration, smooth and consistent performance, and reduces the risk of repeat failures. This approach protects internal components and maintains long-term drivability for Ram trucks and other vehicles using the ZF 8-speed transmission.

Houston Engines offers remanufactured ZF 8HP transmission units upgraded with improved clutch materials, recalibrated valve bodies, and pressure-tested torque converters. Each reman build meets or exceeds OEM durability standards and includes warranty coverage for added peace of mind. For customers considering a used transmission, Houston Engines provides expert guidance to evaluate condition, service history, and compatibility with the specific vehicle application, ensuring reliable performance, extended transmission life, and confident operation under all driving conditions.

Installation and Technical Support Information

Proper installation is critical to ensuring the longevity and performance of any ZF 8HP reman transmission. Always follow the manufacturer’s torque specifications on the bellhousing and use new flexplate bolts to prevent misalignment. Improper tightening can lead to vibration, seal failure, or torque converter mis-seating. During installation, confirm converter engagement by rotating the input shaft and verifying three distinct seating clicks before mating the transmission to the engine. These steps help guarantee smooth operation and protect internal components from premature wear.

Using the correct fill procedure specified by ZF is equally important. Fluid temperature must be within the recommended range, and the vehicle should remain on level ground during final fluid checks. Improper filling can cause line pressure issues, delayed gear response, or inconsistent shift quality. Adhering to ZF 8-speed service intervals from the first installation ensures long-term hydraulic integrity and preserves the transmission’s operational reliability over time.

After installation, perform the adaptive relearn process using a professional scan tool. This procedure allows the transmission control module to adjust clutch fill times, optimize shift logic, and re-establish smooth gear transitions. Skipping this step can result in abrupt shifts, reduced drivability, or temporary performance inconsistencies until the system self-corrects.

Houston Engines provides comprehensive install guides, pre-fill specifications, and post-installation support for all ZF 8HP replacement units. Technicians and vehicle owners can rely on their technical team for setup assistance, diagnostics, and warranty registration. For replacement options or professional guidance, contacting Houston Engines ensures a successful installation and long-term transmission reliability.

Get our latest news and promos

QUALITY ASSURED

SATISFACTION GUARANTEED

UNPARALLELED SUPPORT

Houston Engines

Proud Member

Social Media

Payments Accepted

Ship Via