Mon - Fri: 8am - 5pm, Sat - Sun: Closed

6-36 Month Warranties

We Ship Local.

Hablamos Español.

Connect with

Understanding the Benefits of Engine Remanufacturing

Engine Remanufacturing

High-Quality Remanufactured Engines

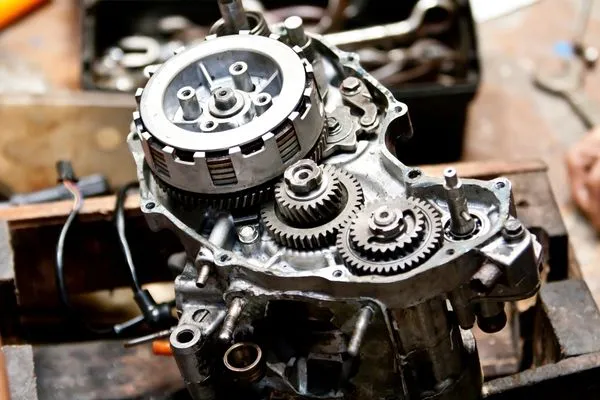

Remanufactured engines Katy offers a high-quality and cost-effective alternative to both new and used engines. The process of engine remanufacturing involves completely disassembling an existing engine, cleaning all components, and replacing any worn or defective parts with new or re-machined ones. This comprehensive rebuild brings the engine back to, or even beyond, its original specifications, performance, and reliability comparable to a new engine.

The remanufacturing process includes several rigorous quality assurance steps to guarantee the quality of remanufactured engines. These steps begin with the complete disassembly of the engine, where each part is thoroughly cleaned and inspected. Components such as bearings, seals, and gaskets are replaced, and the engine block and cylinder heads are machined to precise specifications. The remanufacturing process also involves advanced techniques like magnafluxing to detect cracks and flaws, and each part meets the highest standards of quality.

When comparing remanufactured engine vs new, remanufactured engines offer several advantages. While new engines are built entirely from new parts and are typically the most reliable option, they come at a significantly higher cost.

Remanufactured engines, on the other hand, provide similar reliability and performance at a fraction of the cost. This makes them an attractive option for those looking for cost-effective engines without compromising on quality. Local suppliers like My Transmission Experts and Car Part Planet provide a wide range of remanufactured transmissions Katy.

When it comes to reliability, GM used engines often emerge as a preferred choice for many drivers and mechanics alike. The term reliable GM used engines is not just a marketing phrase but a reflection of the brand's commitment to durability that continues even beyond the showroom. General Motors has a storied history of producing engines that are built to last, and this legacy carries over into their used engines.

The longevity of GM engines is well-documented, with numerous models consistently reaching or exceeding the 200,000-mile mark with proper care. This track record is a significant factor in the high customer satisfaction ratings GM enjoys. Owners of GM vehicles often report fewer major mechanical issues compared to other brands, which is a testament to the engines' robust design and engineering.

Extended Lifespan of Remanufactured Engines

Remanufactured engines offer a significant advantage in terms of longevity and durability compared to used engines and can even rival new engines in performance and lifespan. The process of engine remanufacturing involves a complete teardown, thorough cleaning, detailed inspection, and rebuilding of the engine to meet or exceed original equipment manufacturer (OEM) specifications. This meticulous process is a key factor contributing to the extended lifespan of remanufactured engines.

One of the primary benefits of remanufactured engines is their extended lifespan. These engines are rebuilt using advanced techniques and high-quality parts that are often upgraded from their original designs. For example, during the remanufacturing process, components such as bearings, gaskets, and seals are replaced with new ones, and difficult parts like the crankshaft and cylinder heads are re-machined to precise specifications. This comprehensive approach results in an engine that is not only as good as new but often more reliable due to the elimination of initial manufacturing flaws.

Several factors contribute to the longevity of remanufactured engines. First, the use of OEM or better-quality parts during the rebuild clears that the engine components are robust and durable. Remanufactured engines undergo rigorous testing to verify their performance and reliability.

This includes stress tests, pressure tests, and operational testing under various conditions to simulate real-world driving scenarios. Such thorough testing helps identify and rectify potential issues before the engine is installed in a vehicle.

Performance and Efficiency of Remanufactured Engines

Engine remanufacturing offers significant benefits, providing engines that perform on par with new ones while being more environmentally friendly and cost-effective. The remanufacturing process involves completely disassembling the engine, thoroughly cleaning and inspecting all components, and replacing worn or defective parts with new or refurbished ones. That the engine not only meets but often exceeds original equipment manufacturer specifications.

Remanufactured engines are built to deliver reliable and efficient performance. The rigorous engine rebuilding process involves advanced techniques such as magnafluxing and ultrasonic testing to detect and correct any flaws. This meticulous attention to detail affirms that quality remanufactured engines provide optimal performance. Companies like Gearhead Engines and Jasper Engines & Transmissions emphasize that remanufactured engines undergo extensive testing, including compression and oil pressure tests, that they operate smoothly and efficiently.

One of the significant benefits of remanufactured engines is their efficiency. By reusing existing engine blocks and components, the remanufacturing process conserves resources and reduces the environmental impact compared to manufacturing new engines. This makes remanufactured engines an eco-friendly choice for vehicle owners. Advancements in remanufacturing techniques often incorporate updates that improve fuel efficiency and reduce emissions, aligning with modern environmental standards. When comparing remanufactured engine vs new, cost-effectiveness is a major advantage. Remanufactured engines are typically less expensive than new engines, offering a cost-effective solution for those needing a reliable replacement.

This makes them particularly attractive for budget-conscious consumers who do not want to sacrifice quality or performance. The savings can be substantial, making remanufactured engines a smart financial choice.Remanufactured engines often come with warranties that rival those of new engines, providing additional peace of mind. Jasper Engines & Transmissions offers a warranty on their remanufactured engines, covering parts and labor. This warranty makes sure that any potential issues are promptly addressed, increasing the reliability and lifespan of the engine. The comprehensive warranty coverage underscores the confidence that manufacturers have in the quality and durability of their remanufactured products.

Eco-Friendly Benefits of Engine Remanufacturing

Engine remanufacturing is an environmentally conscious process that significantly reduces waste and conserves resources, contributing to the overall sustainability of automotive practices. By reusing and refurbishing existing engine components, remanufacturing minimizes the need for new raw materials and reduces the carbon footprint associated with producing new engines.

The cost-effectiveness of a used GM engine is a significant consideration, leading many to ask, Is a used GM engine worth it? The answer often lies in the balance between price and performance. Used GM engines typically offer substantial savings over their new counterparts, often amounting to thousands of dollars. This price difference can make a used engine an attractive proposition for those looking to extend the life of their vehicle without the financial burden of a new engine.

Moreover, the value proposition of a used GM engine extends beyond the initial purchase price. The depreciation curve is less steep for used engines, meaning they retain their value better over time compared to new engines that depreciate rapidly once they're off the lot. When you factor in the longevity that GM engines are known for, the cost per mile can be significantly lower, enhancing the overall worth of a used engine. For budget-conscious consumers, this makes a used GM engine not just a viable option, but a financially savvy one as well.

One of the primary benefits of remanufactured engines is their contribution to reducing environmental impact. The process involves taking a used engine, disassembling it completely, cleaning all components, and replacing any worn or defective parts with new or re-machined ones.

This reduces the demand for new materials and lowers greenhouse gas emissions associated with manufacturing new engines. Companies like Cummins Inc. have highlighted that remanufacturing can cut emissions by up to 50% compared to new engine production, making it a key strategy in the push for more eco-friendly engines The engine rebuilding process is meticulous and thorough, that each remanufactured engine meets or exceeds the original equipment manufacturer (OEM) specifications. This includes precision machining and the use of high-quality replacement parts, which not only extends the engine's lifespan but also improves its efficiency and performance.

Comprehensive Testing of Remanufactured Engines

Engine remanufacturing involves a meticulous process to confirm that the engines meet or exceed original equipment manufacturer specifications. One of the key components of this process is thorough and rigorous testing, which guarantees that quality remanufactured engines perform reliably and efficiently. Remanufactured engines undergo several stages of testing to verify their performance and reliability. This includes pressure tests, compression tests, and live-run tests.

Companies like Jasper Engines & Transmissions use advanced diagnostic tools to check oil pressure, vacuum, and compression levels, so that each engine operates smoothly under various conditions. This rigorous testing process helps identify and rectify any potential issues before the engine is installed in a vehicle. During the remanufacturing process, every component of the engine is inspected for wear and tear. Crankshafts, for example, are precision-machined to exact tolerances and undergo micro-polishing to provide smooth operation and reduce bearing wear.

Camshafts are inspected for wear, and cylinder heads are tested for cracks and reconditioned to meet stringent specifications. The extensive testing clears that remanufactured engines Houston are as reliable as new engines. This thorough process not only verifies the engine's performance but also contributes to its extended lifespan. High-quality testing procedures guarantee that remanufactured engines can handle the stresses of daily use, providing vehicle owners with a dependable and cost-effective engine solution.

Remanufactured engines are an environmentally friendly choice. The remanufacturing process involves reusing existing engine components, which reduces waste and conserves resources. This approach minimizes the environmental impact compared to manufacturing new engines, making remanufactured engines a sustainable option for eco-conscious consumers.

Get our latest news and promos

QUALITY ASSURED

SATISFACTION GUARANTEED

UNPARALLELED SUPPORT

Houston Engines

Proud Member

Social Media

Payments Accepted

Ship Via