Mon - Fri: 8am - 5pm, Sat - Sun: Closed

6-36 Month Warranties

We Ship Local.

Hablamos Español.

Connect with

Why is the Cummins 6.7L so popular?

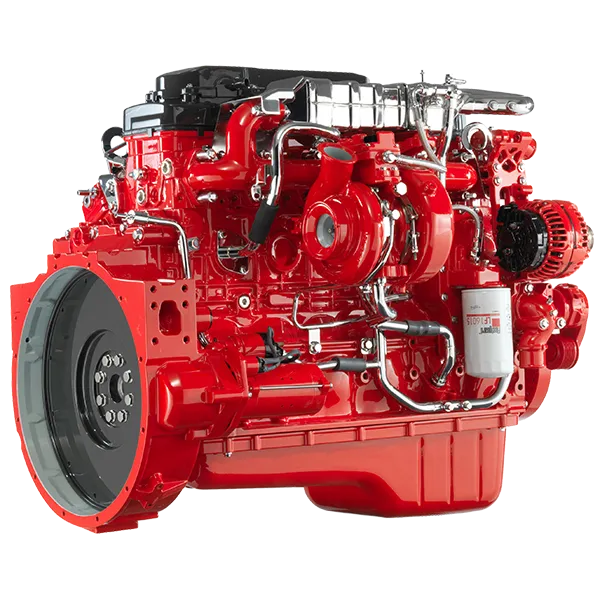

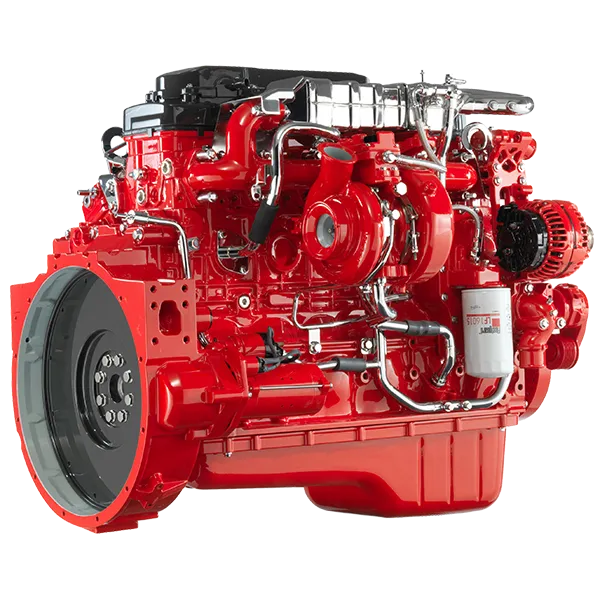

Cummins 6.7L Engine Review

A Workhorse Built for Performance

The Cummins 6.7L engine first hit the market in 2007, built to replace the 5.9L and meet rising emissions standards. Designed for heavy-duty applications, it combined modern emissions control systems with the proven reliability Cummins was already known for. At its core is a cast iron block, high-pressure common rail fuel injection, and a variable geometry turbocharger—all engineered to deliver consistent power under load.

Early versions produced around 350 horsepower and 650 lb-ft of torque, with newer variants reaching up to 420 horsepower and 1,075 lb-ft in commercial setups. Its broad powerband and rugged durability made it a favorite for diesel enthusiasts and work truck owners. The 6.7L continues to perform, backed by Cummins’ ongoing innovations.

The Cummins 6.7L engine, known for its torque and durability, powers reliable vehicles like the Ram 2500 and 3500 trucks. Valued for exceptional towing strength, fuel efficiency, and minimal maintenance, it’s a top choice for both work and everyday use. As one of the few inline-six diesel options in its class, the 6.7L offers smooth operation and long service life. A remanufactured engine ensures these trucks continue delivering top performance for years, making it an ideal solution for lasting reliability.

Trusted by Professionals and Enthusiasts

Heavy-duty users across industries rely on the Cummins 6.7L to perform in tough conditions. Whether it's installed in a Ram 3500 hauling heavy trailers or powering a vocational chassis for utility work, the engine consistently delivers. It’s also popular in off-road and tuning communities because of its high output potential, durability, and simple mechanical layout that allows for easier modifications and long-term serviceability.

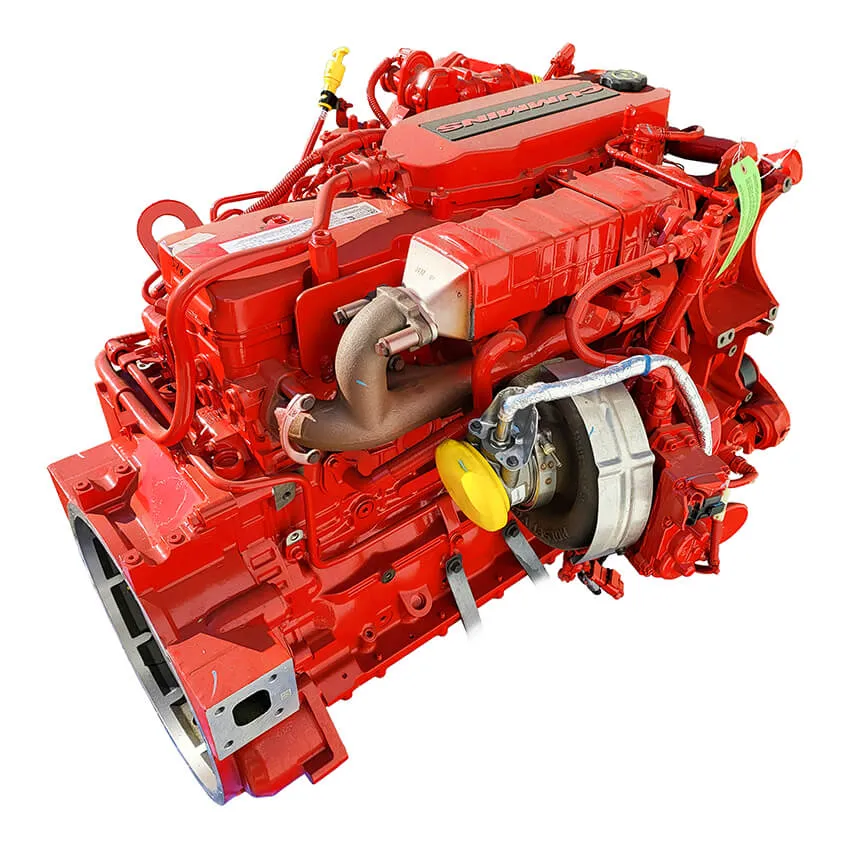

Factory-equipped versions use an advanced exhaust after-treatment system to stay compliant with emissions laws while still producing dependable torque and throttle response. The system includes components like the diesel oxidation catalyst (DOC) and selective catalytic reduction (SCR), helping reduce harmful emissions without sacrificing performance. It also features robust internals, such as forged steel connecting rods and a graphite-coated piston skirt for reduced friction, improved durability, and better heat resistance over time.

These specs and design features combine to give the Cummins 6.7L a reputation as a work-ready diesel with a long lifespan and solid aftermarket support. Known for its durability and ease of service, it’s a top choice among fleet operators and truck enthusiasts alike. Owners often report reaching well over 300,000 miles with proper maintenance, making it a smart long-term investment for those in commercial, agricultural, or recreational use where reliability and longevity truly matter.

Known Issues and What to Watch For

Like any engine, the Cummins 6.7L isn't immune to mechanical concerns. One of the most common complaints revolves around the EGR system and DPF clogging, particularly in models that spend a lot of time in stop-and-go driving. These emissions systems were added to meet federal regulations, but they can become problematic without proper care. Excessive idling and short trips can prevent the DPF from regenerating properly, leading to soot buildup and reduced performance. Routine cleaning and highway driving can help mitigate these issues and extend the life of the emissions components.

The fuel system is another component that needs monitoring. High-pressure fuel pumps, especially the CP4.2 pump found in certain years, have had reliability issues that can lead to catastrophic failures. When these pumps fail, they can send metal shavings through the fuel system, damaging injectors and other components. Many owners opt to retrofit these with a CP3 pump upgrade, restoring both peace of mind and reliability.

Turbo actuator failure is also worth noting. This component controls the variable geometry turbo and, if it fails, can lead to reduced power and limp mode. Fortunately, aftermarket solutions and rebuild kits are widely available. Upgraded actuators offer better durability and performance. If you're considering a remanufactured Cummins 6.7L engine, many of these issues are addressed in the rebuild process through updated components and improved assembly standards.

Regular maintenance and quality fuel can extend the engine’s life significantly. Scheduled oil changes, fuel filter swaps, and periodic EGR cleanings are essential to keep it running strong. With proper upkeep and attention to known weak points, the Cummins 6.7L remains one of the most respected powerplants in the diesel market and continues to be a reliable choice for both work and recreation.

Why It’s Still a Popular Diesel Pick

One reason the 6.7L Cummins has remained so widely used is its perfect balance between power and simplicity. Unlike V8 competitors, its inline-six design provides fewer moving parts, which translates to less long-term wear and tear. The engine layout also makes it easier to access components for repairs, appealing to fleet mechanics and DIYers alike. This simplicity is a major advantage in work environments where uptime and ease of service are critical. Its reputation for being both powerful and easy to maintain has kept it in high demand across various industries.

The aftermarket support is another key factor. With so many of these engines on the road, replacement parts and performance upgrades are easy to find. There’s a wide selection of tuners, turbochargers, fuel system upgrades, and emission system solutions available to fit different goals and budgets. Whether someone wants more towing strength, better fuel economy, or extended engine life, the Cummins 6.7L is built to support those goals. That’s why it continues to be a top choice for diesel truck rebuilds.

Remanufactured Options Extend Its Lifespan

When the time comes for a replacement, many owners choose a remanufactured version instead of a full engine swap or expensive repairs. These engines are completely disassembled, cleaned, machined, and rebuilt with new components, making them a reliable option without the cost of brand-new units. Remanufactured engines provide the same level of performance and dependability while offering a more budget-friendly solution for those managing fleet expenses or personal truck projects.

At Houston Engines, remanufactured Cummins 6.7L options are built with upgraded parts to correct known factory defects. The reman process includes pressure testing, cylinder head resurfacing, and full part replacements. These steps ensure each engine meets or exceeds OEM performance standards. All units are inspected and assembled by experienced technicians who understand the demands of diesel performance.

Buyers can also find complete Cummins engine packages, which simplify the swap process. These packages come with everything needed for installation, minimizing downtime and making them ideal for shops and fleet operators. This all-in-one approach saves time and ensures compatibility with existing systems. Contact houston engines to learn more about the complete packages available for your engine swap needs.

Choosing remanufactured not only saves money—it also contributes to sustainability. By recycling existing cores and refurbishing key components, it's a smart option that benefits both the engine owner and the environment. With continued demand and support from trusted suppliers, the 6.7L Cummins continues to power on, thanks in part to the strong availability of reman options across the U.S., making it a dependable solution for the long haul.

Get our latest news and promos

QUALITY ASSURED

SATISFACTION GUARANTEED

UNPARALLELED SUPPORT

Houston Engines

Proud Member

Social Media

Payments Accepted

Ship Via