Mon - Fri: 8am - 5pm, Sat - Sun: Closed

6-36 Month Warranties

We Ship Local.

Hablamos Español.

Connect with

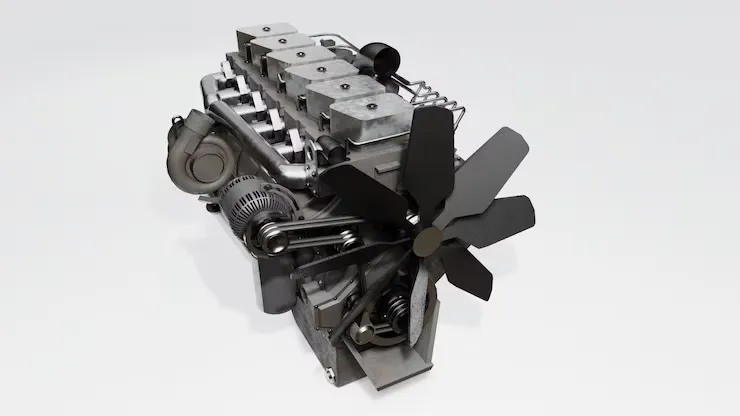

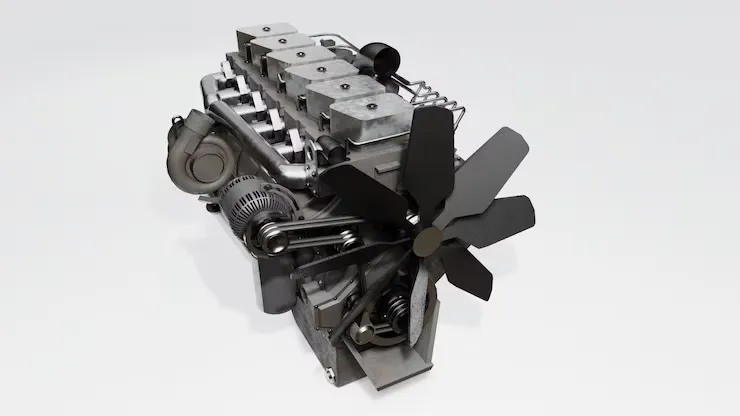

Complete Guide to GM 5.3L Vortec Engine Variants

GM 5.3L Engine Review

Engine Evolution Explained with Key Features and Specs

The GM 5.3L Vortec engine has been a staple in the automaker’s truck and SUV lineup since its Gen III debut in 1999. Known internally as the LM7, it quickly became a popular powerplant in the Silverado, Sierra, Suburban, Tahoe, and Yukon due to its balance of power, efficiency, and reliability. The engine’s 5.3-liter displacement comes from a 96mm bore and 92mm stroke, delivering between 270–320 horsepower depending on the model year and application.

By the time Gen IV versions rolled out, updates such as Active Fuel Management (AFM) and variable valve timing were added. These enhancements, while boosting efficiency, sometimes led to issues like oil consumption. Still, the Gen IV 5.3L stayed reliable in remanufactured GM builds.

Introduced around 2014, the Gen V EcoTec3 5.3L engines brought direct injection, enhanced airflow, and stronger internals. These improvements increased output to 355 horsepower in many newer trucks and SUVs. Some Gen V versions, such as the L83, use LT-based engine codes but uphold the tradition of GM’s adaptable, swap-friendly V8s. Alongside added power, these engines deliver better fuel efficiency and greater durability, continuing the Vortec legacy with modern technology and performance suited for both daily driving and custom builds

Used in Trucks and SUVs for Enhanced Performance

The 5.3L engine has been widely used across GM vehicles, making it a core offering in multiple platforms. From workhorse trucks like the Chevy Silverado 1500 and GMC Sierra to family-oriented SUVs such as the Yukon XL and Chevy Tahoe, the engine has proven adaptable to a variety of needs. Many vehicle owners looking to extend the lifespan of their GM models turn to remanufactured 5.3L engines, providing a cost-effective alternative to costly replacements.

The 5.3L's versatility extends beyond GM vehicles, thanks to its small-block LS-style architecture. It’s a popular choice for LS swap projects, offering impressive power and performance at a reasonable price. Whether used in muscle cars, older trucks, or performance builds, the 5.3L engine remains a top pick for enthusiasts and restorers looking for a reliable, affordable powerplant that delivers solid performance without breaking the bank.

First-generation 5.3L Vortec engines, such as the LM7 and L59, are frequently sourced from salvage vehicles for performance builds and upgrades. Their widespread availability and low cost make them an attractive option for enthusiasts building custom projects or replacing worn-out engines in daily drivers. These engines offer a solid foundation for modifications, providing a reliable and affordable solution for those seeking enhanced performance. Their popularity continues to grow due to their versatility and strong aftermarket support for upgrades

Performance Strengths and Weaknesses of the Engine

One of the biggest strengths of the 5.3L Vortec engine is its reliability. Gen III versions are particularly well-regarded for their longevity, thanks to simple yet durable architecture. These engines use cast-iron blocks with aluminum heads and traditional pushrod valvetrains, which makes them easier to service and upgrade compared to modern overhead cam designs. The traditional pushrod setup is also known for being less complex and more robust. Additionally, the aftermarket support for the 5.3L platform is vast, offering everything from performance cams to turbo kits, making it a favorite among automotive enthusiasts looking to build or upgrade their vehicles.

However, the engine has its weak points. Gen IV versions with AFM (Active Fuel Management) tend to suffer from lifter collapse and oil consumption issues, especially under heavy mileage. The AFM system, designed to improve fuel efficiency by deactivating half of the cylinders under light load, often causes long-term reliability concerns. It’s common to disable AFM with a tune or switch to non-AFM lifters during rebuilds to avoid these problems. The Gen V models also introduced direct injection, which improved power and fuel economy but added complexity in maintenance and tuning. Direct injection helps with performance but may require more frequent maintenance due to carbon buildup on intake valves.

Still, many of these issues can be mitigated during the remanufacturing process, where components are upgraded or replaced. These improvements make remanufactured 5.3L engines a smart solution for fleet vehicles, daily drivers, and custom builds alike, offering peace of mind for owners looking to get the most out of their engines.

Another reason for this engine’s popularity is its adaptability. Whether you need a low-mileage replacement or a fully rebuilt high-performance version, the 5.3L offers plenty of potential. With proper care and smart upgrades, these engines can easily push past 300,000 miles, especially in platforms like the Chevy Suburban or GMC Yukon.

Frequent situations requiring common replacements or swaps

The most common reason drivers replace their 5.3L engine is age and mileage. GM’s trucks and SUVs, particularly in Texas and the southern U.S., are put through heavy use with frequent towing, hauling, and long commutes. Over time, high mileage can wear down critical engine components, such as cylinder walls, valve seals, and lifters—especially in Gen IV models with AFM.

To address these issues, many customers choose a remanufactured 5.3L Vortec engine over a used one. This option offers peace of mind, often backed by a warranty for extra security. A remanufactured engine provides better reliability and performance compared to a used engine, which can carry more risk and uncertainty. Engine swaps are also common, especially for those looking to upgrade their vehicle’s performance. This is particularly true for those replacing a smaller engine, like the 4.8L, with a 5.3L. The upgrade gives more torque and horsepower, making it a popular choice for those seeking enhanced towing, hauling, and overall vehicle performance.

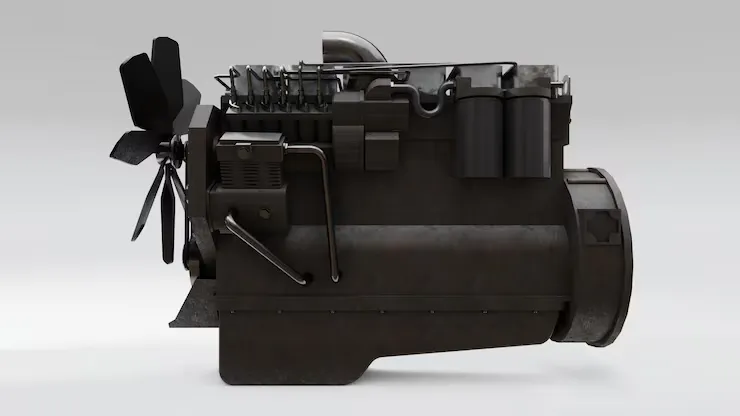

Why It’s a Great Remanufacturing Candidate

The 5.3L Vortec’s mix of widespread availability, simple design, and upgrade options make it ideal for remanufacturing. Cast-iron block Gen III engines are particularly attractive to rebuilders due to their robustness and resistance to cracking under high horsepower loads. During the remanufacturing process, rebuilders typically install upgraded bearings, valve seals, pistons, and gaskets, bringing the engine back to like-new or even better condition. This makes the 5.3L a reliable choice for those seeking long-term performance.

The Gen IV and Gen V versions of the 5.3L engine benefit from improved fuel systems and more durable internals, which are frequently enhanced during remanufacturing. These improvements help increase the engine's performance and longevity, while also addressing common factory flaws, such as AFM-related lifter issues. Whether replacing a failed engine or building a restomod, a remanufactured 5.3L offers modern efficiency and dependability.

Remanufactured 5.3L engines are particularly popular among truck and SUV owners because they allow their vehicles to remain in service without sacrificing reliability. With proper installation and maintenance, a reman engine can provide many years of dependable service, making it a cost-effective alternative to purchasing a new vehicle. This is why the 5.3L remains one of the top-selling units in the remanufactured engine market. Contact Houston Engines for more details on how a 5.3L remanufactured engine can keep your vehicle running smoothly.

The widespread popularity of the 5.3L engine ensures a steady supply of cores and replacement parts. As demand grows, advancements in remanufacturing technologies continue to improve the rebuilding process, keeping the engine relevant for various applications.

Get our latest news and promos

QUALITY ASSURED

SATISFACTION GUARANTEED

UNPARALLELED SUPPORT

Houston Engines

Proud Member

Social Media

Payments Accepted

Ship Via